There are many factors that can make a web wrinkle. The causes could be due to imperfect product received from suppliers to in house environmental and/ or processing issues that compromises the properties of the web. When determining the source of your web wrinkles, make sure to consider the following circumstances. The 5 circumstances we will go over will be covered over two weeks. We will cover 3 in this week's tech tip and in the next week's tech tip we will cover the next 2 circumstances.

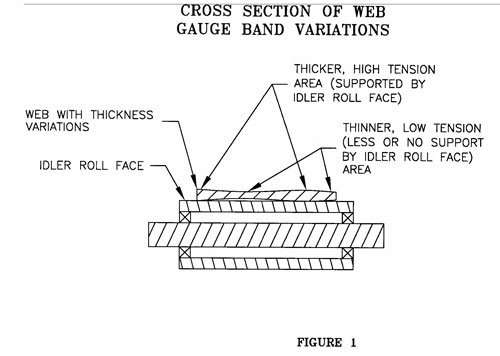

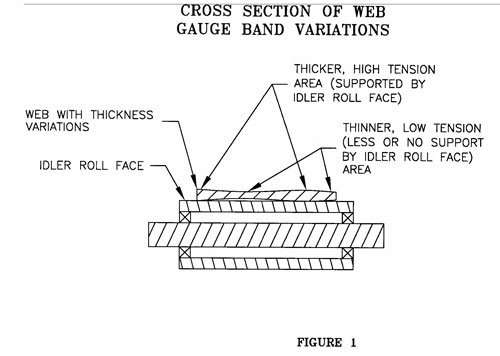

- Gauge band (thickness) variations across the web width, shown below. Cross machine direction shown below will cause wrinkles because tensions will vary across the web width. These tension variations will cause tensile stress in the thicker areas and compression in thinner areas. This compression causes wrinkles.

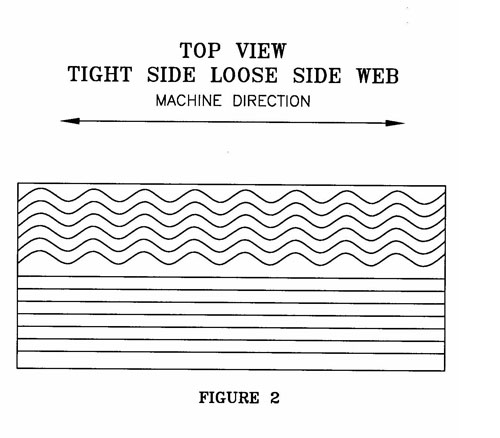

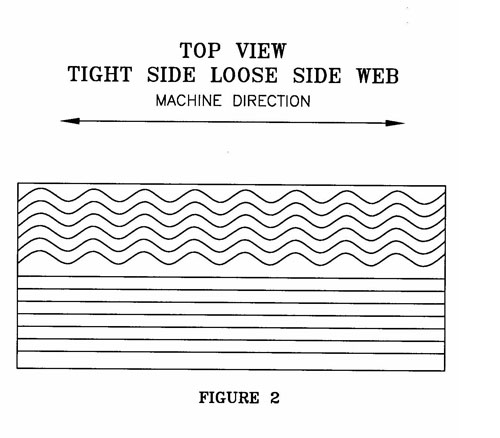

- Tight side/loose side, shown below. This condition is caused by the web being longer (linearly), on one side than the other, in the machine direction. If you were to lay flat an extremely long length of material in this condition under no tension, it would actually arc instead of being straight. This condition again creates tensile stress on the tight (short) side and compression on the loose (long) side, causing wrinkles.

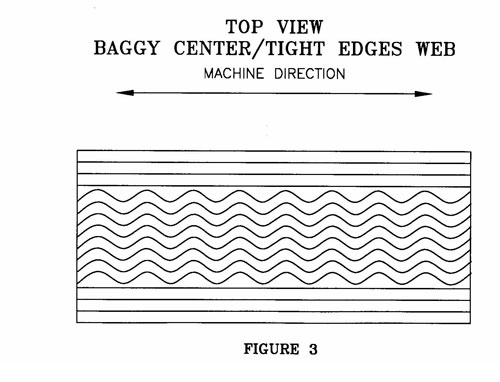

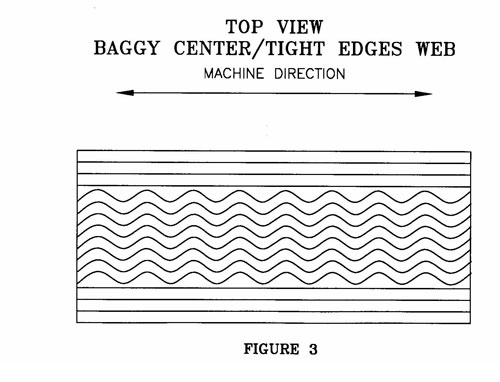

- Baggy center, tight edges, shown below. The web being longer in the center than the two edges, in the machine direction, causes this condition. If you were to lay material with this characteristic, flat, then you would see ripples or bubbles develop in the center while the edges were straight and flat. In a converting process, webs with this material characteristic will wrinkle because most of the tension that is typically evenly distributed across the full width is mostly distributed on the shorter (machine direction) edges than longer (machine direction) center. Tensile stress on the edges will create lateral compression in the center of the web, causing wrinkles.

Check back next week for the next 2 causes of web wrinkles.

|