|

Tech tip for the week of February 16, 2026 |

Expanding Surface Anti-Wrinkle Rollers by Double E Group

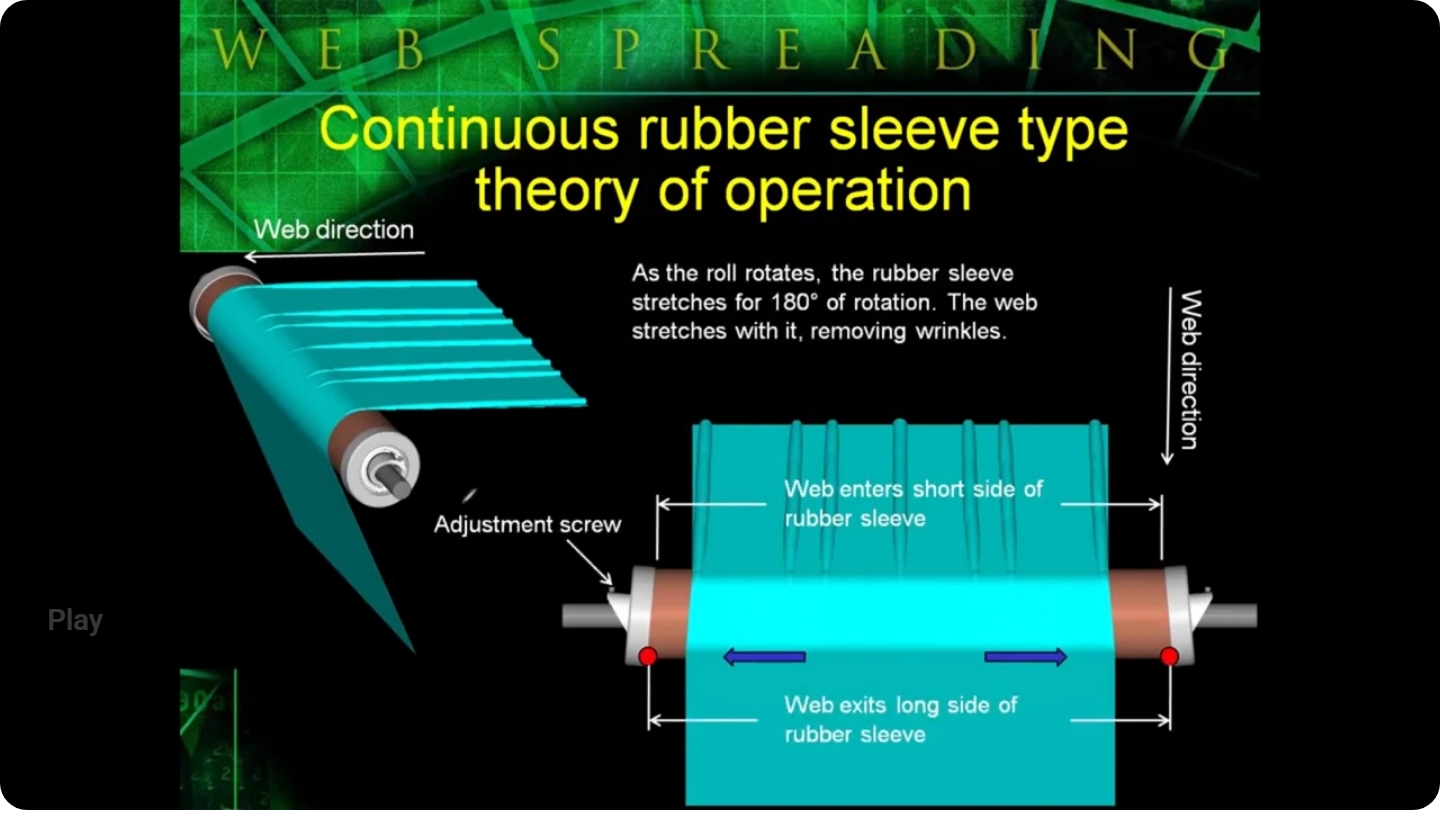

If you process paper, film, foil, textile or nonwoven webs in a converting process then you, most likely, must deal with web wrinkles on a daily basis. This mini-presentation is the last in a series of eight, covering spreader and anti-wrinkle roller technology. Here, we discuss expanding surface type anti-wrinkle rollers, which includes converting industry's premier anti-wrinkle system.

CAC and WrinkleSTOP are Double E Group brands.

This TechTip brought to you by the web handling experts at Double E Group. We provide the technology, engineering and equipment you need for web handling in your converting process. Contact us today to learn more and receive a proposal.

www.ee-co.com

Click to stop wrinkles in your paper, film, foil, textile or nonwoven:

www.ee-co.com/products/cg/wrinklestop-no-bow-spreader-roller

© 2026 Converter Accessory Corporation

Click to learn how WrinkleSTOP works for you!

Join us and discuss this tech tip or anything converting at our LinkedIn Group page. This groups function is to develop into a beneficial discussion of all things converting, thus benefiting the industry as a whole - click here for our LinkedIn Group page

**DISCLAIMER - A great deal of time has been invested in the development of our weekly tech tips. To the best of our knowledge, they are accurate. It is up to the user to verify all results.

THE AUTHOR ASSUMES NO LIABILITY CONNECTED WITH THE USE OF THIS INFORMATION OR THE RESULTS OBTAINED FROM IT.