|

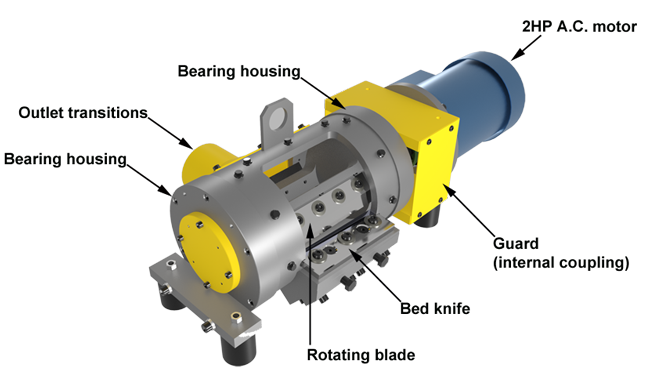

Trim-AX™ Heavy Duty Dual Bladed Chopper View the Trim-Ax™ Chopper in action! Click to view the Fox TrimAway® System and Trim-Ax™ Chopper in action!

Internal view, shown without guards and transition connectors Trim-AX™ Heavy Duty Chopper

CAC's Trim-AX heavy duty chopper utilizes a superior design to chop extemely light to very thick and heavy materials. Trim-AX is precision engineered with dual bearing support between rotor and each bearing housing. It's all steel construction is manufactured using precision CNC machining centers to ensure very tight tolerances between rotating blade and bed knife. Vibration, noise and maintenance is all kept to minimum due to superior engineering, design and manufacturing practices of Trim-AX choppers.

Specifically designed to fit CAC's FOX TrimAway® and FOX Runner® pneumatic waste removal systems, Trim-AX choppers offer seamless integration with CAC's line of pneumatic waste removal systems. Trim-AX may also be integrated into existing commercially available and "homemade" systems. Using the Trim-AX allows an air conveyor system to work over longer distances. In addition using the Trim-AX makes waste handling more efficient and chopped trim takes less space in collection bins. Trim-AX™ chopper, internal view

|

(800) 433-2413

(800) 433-2413

(610) 863-6008

//WORKS FOR INSIDE PAGES. NOT FOR INDEX PAGE WHICH HAS IT'S OWN

Trim-AX Chopper

Made in the USA