FOX TrimAway® Pneumatic Conveying Systems | |

|

Unique Approach to Matrix Removal

Traditionally, label and die cut matrix is wound onto a scrap rewind. This method of waste removal and collection has several drawbacks that results in costly machine downtime. Rolls must be changed frequently, resulting in press stoppage. Tension control becomes very difficult at larger roll diameters, resulting in matrix breaks. Label manufacturers may run more expensive, wider than necessary webs to combat matrix breaks. Often times recycling efforts are complicated by the cardboard core necessary to rewind the matrix roll. FOX TrimAway eliminates the need for rewinding matrix. Advantages to using FOX TrimAway matrix removal includes: |

|

|

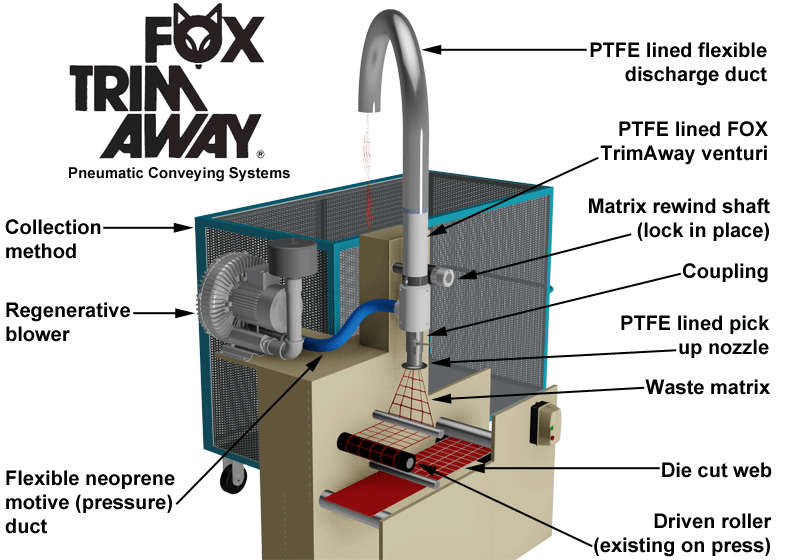

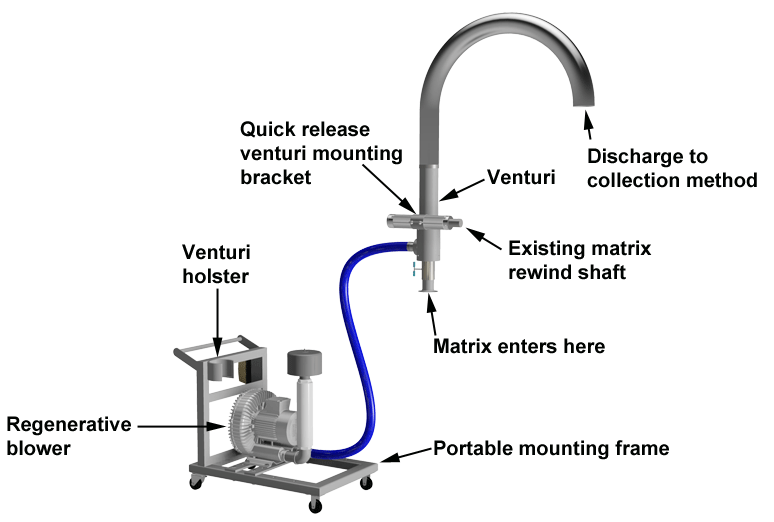

System setup is FAST and EASY. The unique FOX TrimAway venturi is supplied with a special mounting bracket to mount directly to the existing matrix rewind shaft. The matrix threading stays consistent with rewind threading pattern. The blower may be mounted to the floor or machine frame. Duct work is flexible, semi-rigid to ease the routing to the collection method. |

|

|

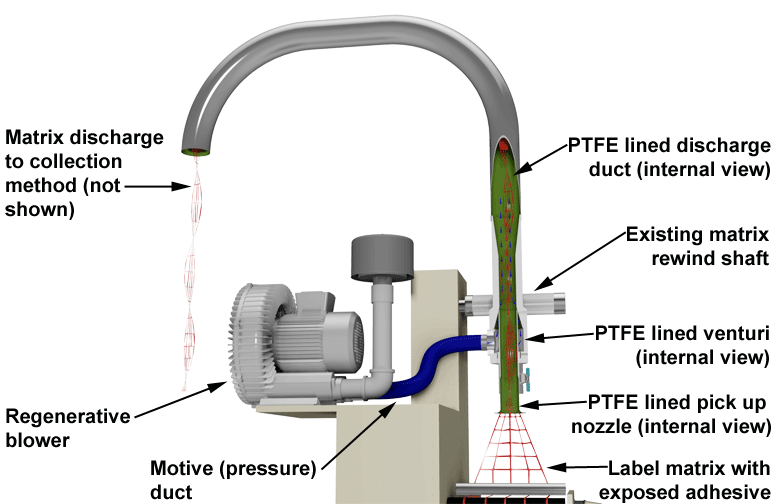

FOX TrimAway pneumatic matrix removal systems utilize powerful and efficient regenerative blowers to generate "motive" air stream. The FOX TrimAway venturi is designed to produce adjustable suction and pressure to convey your waste matrix. The matrix remains in its' typical threading pattern through the machine but instead of rewinding, it is fed into the suction side of the venturi. There is no need to chop the matrix. FOX TrimAway pneumatic matrix removal systems use PTFE lined components to effectively remove matrix with aggressive adhesives. FOX TrimAway does not use oil or powder, keeping your facility clean of contaminants. |

|

Typical Applications Include:

|

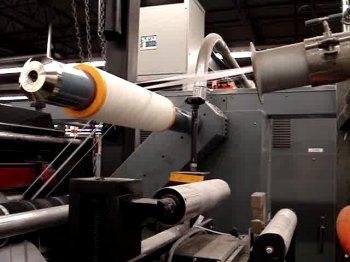

Click here to view the FOX Matrix Removal System in operation |

|

|

||||||||