Curved Axis (bowed) Spreader Roll

Description:

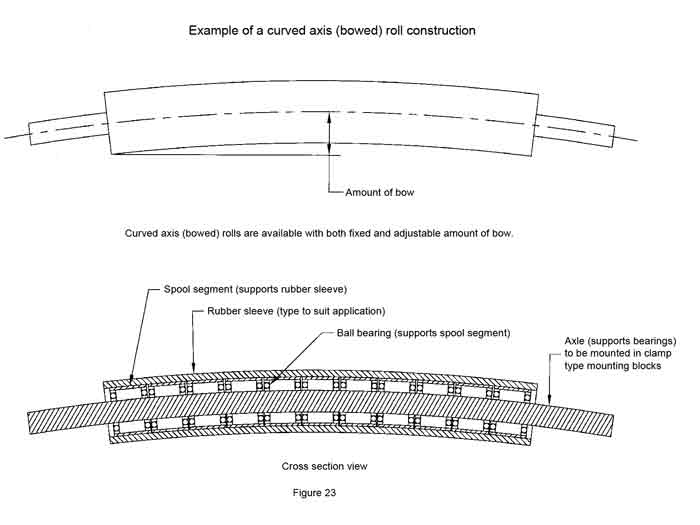

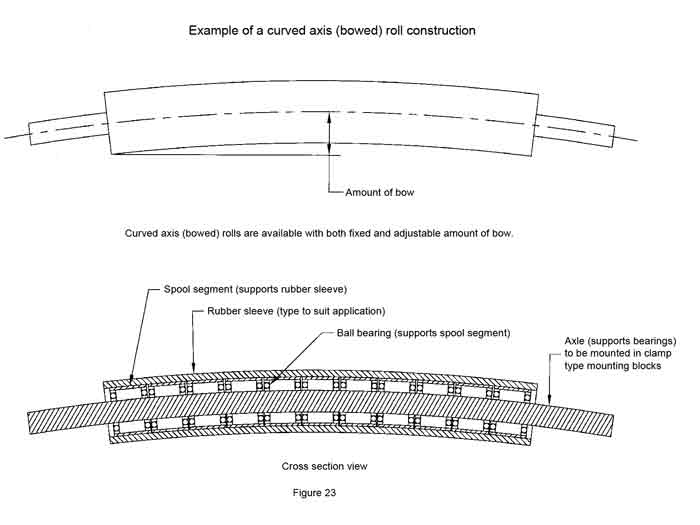

A Curved Axis (Bowed) Roll spreader roll is manufactured exactly as the name states – the center axle of the roll is bowed (not linear). A series of internal ball bearings, supported by the axle, in turn support a rubber sleeve which is continuous across the face. The amount of curve (bow) in the roll face is application dependent and is available in both an adjustable and non-adjustable version. See figure 23.

Theory of operation:

This roll works based on two different spreading principals.

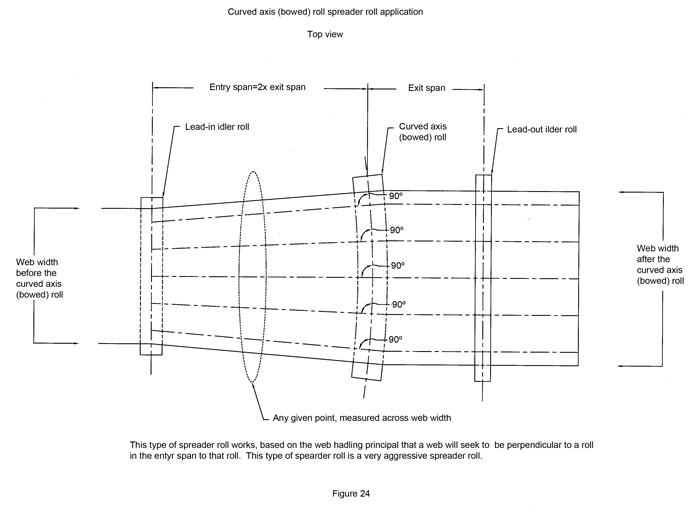

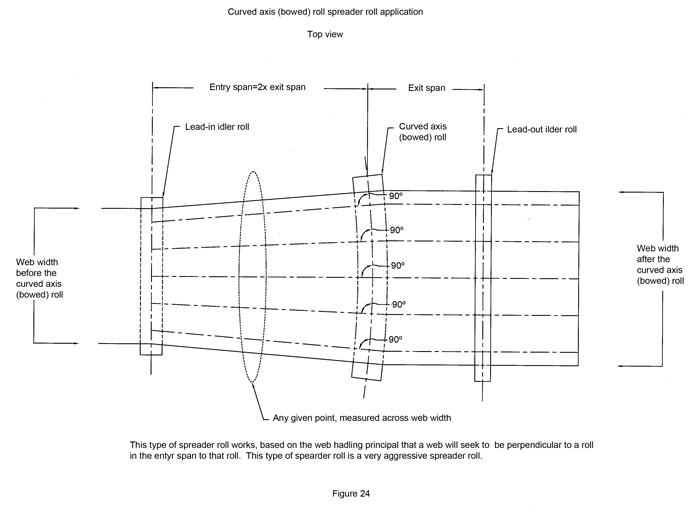

First, as we know, a web will seek to align itself perpendicular to this roll (as long as it is in traction with the roll). This causes the web to spread at any given interval across its width as it tries to maintain the 90 deg. tangent points across the web width.

Second, the rubber sleeve, which spans the roll, is actually narrower on the entry side than the exit side, so as it rotates, the rubber sleeve stretches and the material, laying on top of the rubber surface, stretches with it.

Because this roll normally operates best with minimal wrap angle the first spreading principal does most of the work. Less surface contact between the web and the rubber sleeve means less stretching principal will effect overall spreading. However, the spreading based on web handling principal is hardly affected by wrap angle.

See figure 24.

Recommended wrap angle is usually less than 30 deg. Many times, when it appears a curved axis (bowed) roll is not operating properly, this is due to wrap angles to great for the application. More important than wrap angle, lead-in and lead-out distances are critical. Typical lead-in (entry span) to the curved axis (bowed) roll should be approximately double the lead-out distance (exit span). As you can see in figure 24, most of the spreading caused by this roll is done in the entry span to this roll, so the longer the entry span is, the more spreading will be realized. The exit span should be kept to a minimum so the web stays spread. The longer the exit span is, the more chance there is for the spreading affect to be lost (or the web may return to its wrinkled or natural state).

Advantages:

- This type of spreader roll is an aggressive spreading device.

- This spreader roll is used most often for all types of spreading applications. It is accepted for all facets of converting from narrow web to wide web (it is especially used in wide web applications) and slow speed to high speed.

- This type of spreader roll is used with all types of webs in all types of converting processes.

- It is available with a multitude of different sleeve compounds including abrasion resistance and reinforced (for extremely high speed applications).

- This roll is available in both adjustable and non-adjustable versions.

- It will spread multiple slit widths evenly, the only spreader roll used for this application.

- This roll has a smooth surface, so it will not mark or scratch the surface of the web.

Disadvantages:

- This roll is not linear, so it can permanently distort or tear the center of a web because tension is not evenly distributed across the face of this roll as the web travels over it.

- Maintenance is involved and normally this roll must be returned to the manufacturer to be maintained.

- Because the rubber sleeve is dynamic (it constantly stretches and contracts with each revolution) the rubber sleeve does wear over time.

Curved Axis (Bow) Bar (stationary, does not rotate)

Description:

A Curved Axis (bow) bar spreader bar can be manufactured from steel or aluminum. Many times this spreading device is nothing more than a pipe, curved, using a pipe bender.

Theory of operation:

This spreading device works differently than a curved axis (bowed) roll. The web handling principals that effect web behavior for a curved axis (bowed) roll are not the same as the effects of a curved axis (bow) bar. The web must slip over the face of this bar because it is stationary, it does not rotate. Therefore, the web is not in traction with the bar so the web handling principal that affects the web where a bowed roll is used does not apply here. Instead, the curved axis (bow) bar works based on a tension differential generated by the raised center of the bar. The center, being raised, has the highest tension. The tension decreases toward the bar ends. This tension differential causes wrinkles to be pushed out from the center of the web. The web is attempting to flow through the path of least resistance, which is closest toward the ends of the bar. See figure 25.

Recommended wrap angle for this spreading device can be from 15 deg. to 90 deg. Most applications require minimal wrap. More wrap angle usually means more potential web distortion.

Advantages:

- This spreading device is extremely easy to manufacture. A pipe bender is all that is required.

- This spreading device has a smooth surface.

- Low maintenance (no moving parts).

- This type of spreader will separate slit widths. However, the amount of spreading is completely tension driven. If tension is not accurate and even across the web, slit spacing may not be kept consistent and even.

- This type of spreading device is used with woven, non-woven and paper webs.

Disadvantages:

- This type of spreader is not linear, so it can permanently distort or tear the web center.

- The amount of bow required is application dependent and there is no set formula for generating the amount of bow. Bow amounts are normally determined through trial and error or past experience.

- This type of spreader can scratch and mark the web because the face does not rotate with the web flow.

- This bar will create drag on the web; tension problems may result down stream of this spreading device.

Jeff Damour, Converter Accessory Corp., Wind Gap PA 18091, 800-433-2413

|