FOX TrimAway® Pneumatic Conveying Systems | |

|

Unique Approach to Trim Removal

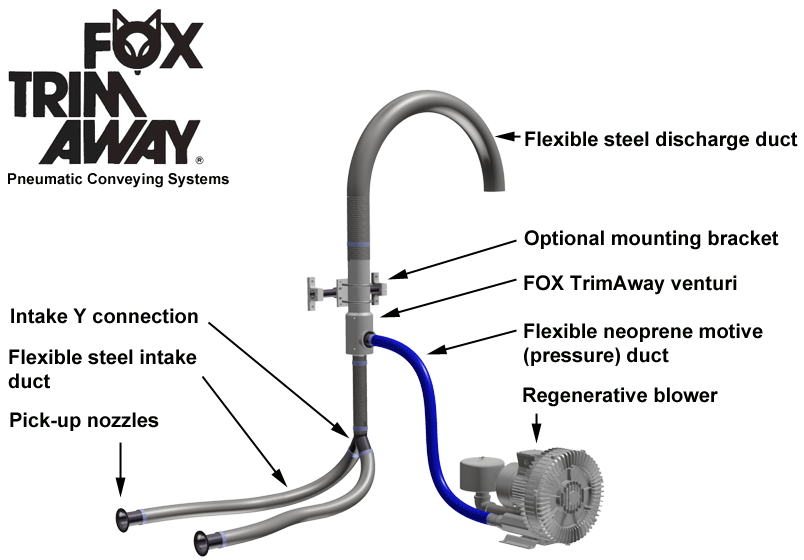

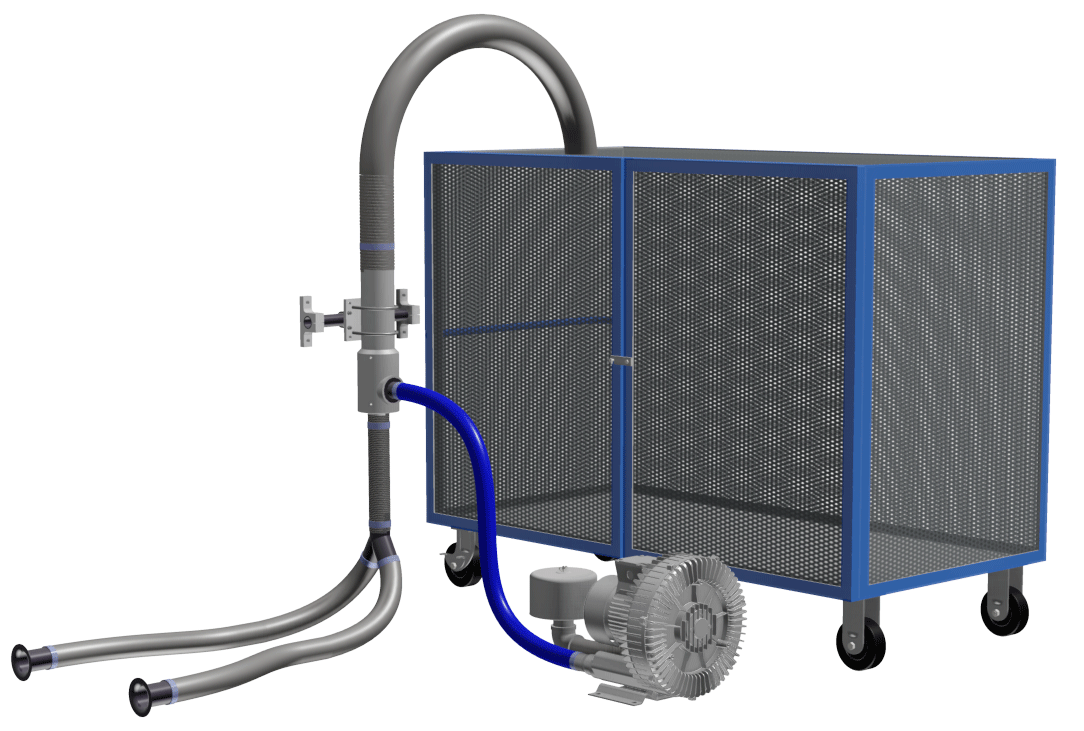

FOX TrimAway systems are unique, utilizing regenerative blowers to generate a motivating air stream. The heart of the system, FOX TrimAway's exclusive venturi, converts the motivating air from the regenerative blower to high velocity suction at the intake and pressure at the discharge. The FOX system yields outstanding performance with genuine energy savings over other types of trim removal systems. They provide real return on investment when used in place of less efficient trim removal systems and systems that utilize compressed air. FOX TrimAway systems are sized and matched to your specific requirements. Systems have an extensive 1/2 horsepower through 20 horsepower blower selection and three sizes of venturi's from which to choose. Rest assured, your system will be sized properly to provide you with the ultimate in performance, initial cost savings and long term operational cost savings. |

|

|

The Venturi Principle

|

|

|

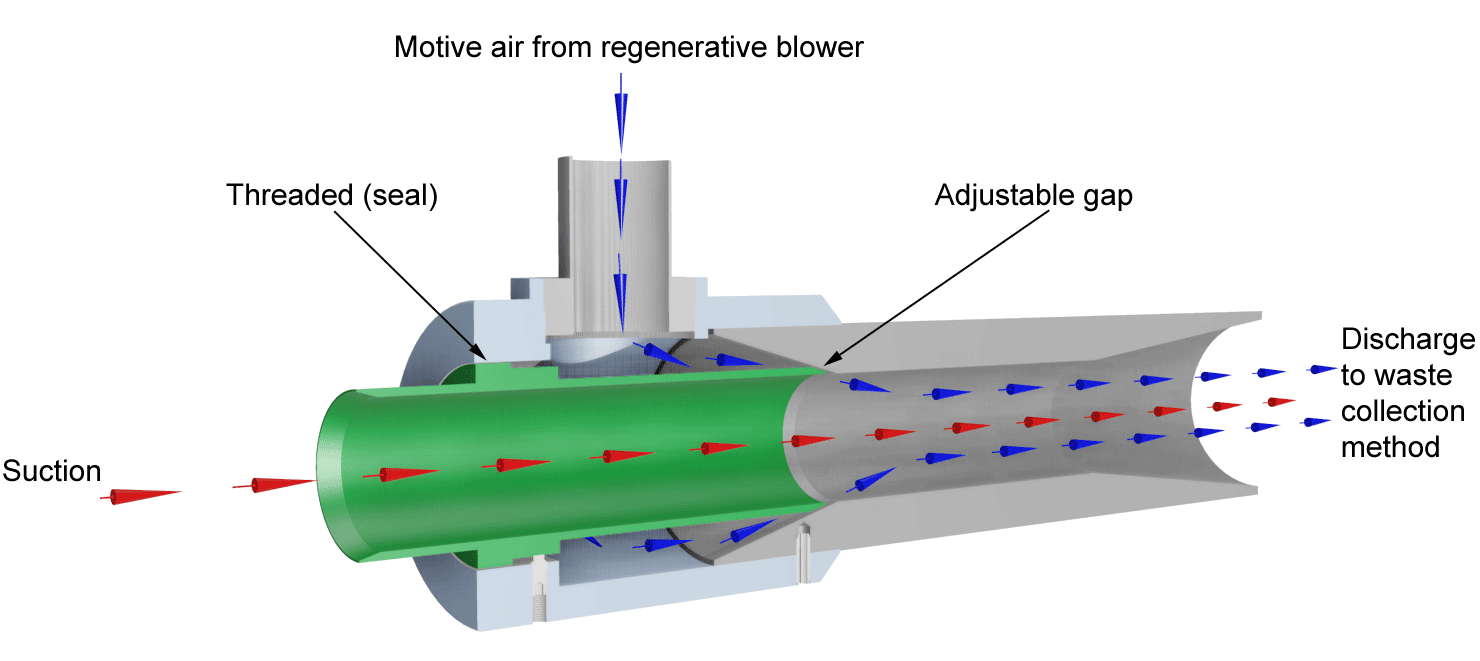

FOX TrimAway systems utilize powerful and efficient regenerative blowers to generate "motive" air from the pressure output of the blower. This air flow is ported into the side of the venturi. The FOX TrimAway venturi is designed so that all of this motive (pressure) air mist, in essence, make a perpendicular turn and flow through the adjustable gap in the venturi. The air is flowing at such a high rate and speed, suction is generated, due to Bernoulli's principal, at the intake side of the venturi. Each FOX TrimAway system is factory tested and adjusted for maximum suction. However, the adjustable gap allows for suction adjustment in the field. The waste (typically edge trim) is fed into the suction side of the venturi and takes a straight path through the venturi. This eliminates the trim from passing through any moving parts. Continuous trim can stay continuous, there is no need for it to be chopped, since it does not pass through any fan blades or other moving parts. System maintenance is very low since there are no moving parts coming in contact with the trim. After the waste enters the venturi and reaches the point where the motive air and suction air join, the waste can be conveyed long (or short) distances with a very powerful stream (combined suction and motive) of air to a waste collection point. Typical Applications Include:

|

|

Click here to view the FOX TrimAway Pneumatic Conveying |

|

Video - Fox Trim Removal System in action

|

|

Standard System Configurations |

|

||||||||||||||||||||||||||||||||

| BLOWER MODEL | |||||||||||||

| click on model# to view drawing | 300AB | 400AB | 350AB | 450AB | 500AB | 501AB | 600AB | 700AB | 800AB | 1015AB | |||

| Venturi | Trim Width |

# of Pickups |

Conveying distance in feet | ||||||||||

| FX1 | Up to 1" | 1 | 25' | 25' | 40' | 40' | N/A | N/A | 50' | ||||

| Up to 1" | 2 | 15' | 15' | 35' | 35' | 50' | 50' | 50' | |||||

| FX2 | Up to 2" | 1 | 25' | 25' | 50' | over 100' | over 100' | ||||||

| Up to 2" | 2 | 20' | 20' | 45' | over 100' | over 100' | |||||||

| FX3 | Up to 3" | 1 | 40' | 70' | over 100' | ||||||||

| Up to 3" | 2 | 35' | 60' | over 100' | |||||||||

|

Instructions:

|

NOTE: This reference chart is for general approximation of system size. Many factors may require a change in system sizing, such as web speed, type of web, web thickness and web stiffness. Please contact CAC for an application specialist (800) 433-2413 to properly size a system to suit your specific requirements. |

| BLOWER MODEL | |||||||||||||

| click on model# to view drawing | 300AB | 400AB | 350AB | 450AB | 500AB | 501AB | 600AB | 700AB | 800AB | 1015AB | |||

| Venturi | Trim Width |

# of Pickups |

Conveying distance in feet | ||||||||||

| FX1 | Up to 1" | 1 | 25' | 25' | 40' | 40' | N/A | N/A | 50' | ||||

| Up to 1" | 2 | 15' | 15' | 35' | 35' | 50' | 50' | 50' | |||||

| FX2 | Up to 2" | 1 | 25' | 25' | 50' | over 100' | over 100' | ||||||

| Up to 2" | 2 | 20' | 20' | 45' | over 100' | over 100' | |||||||

| FX3 | Up to 3" | 1 | 40' | 70' | over 100' | ||||||||

| Up to 3" | 2 | 35' | 60' | over 100' | |||||||||

| Check out our other Pneumatic Conveying Systems solutions |

| Fox TrimAway® Systems | Matrix Removal Systems |

| Fox Runner™ | Fox Combo™ |

| Trim-Ax™ Chopper | Custom Motor Starters |

| System Components | Waste Collection Methods |

| Variable Frequency Drive | Fox TrimAway® Support Center |

| What's new with Trim Removal | Air Flow Data |

Phone (800) 433-2413 - (610) 863-6008

© 2026 Converter Accessory Corporation